PRODUCTS

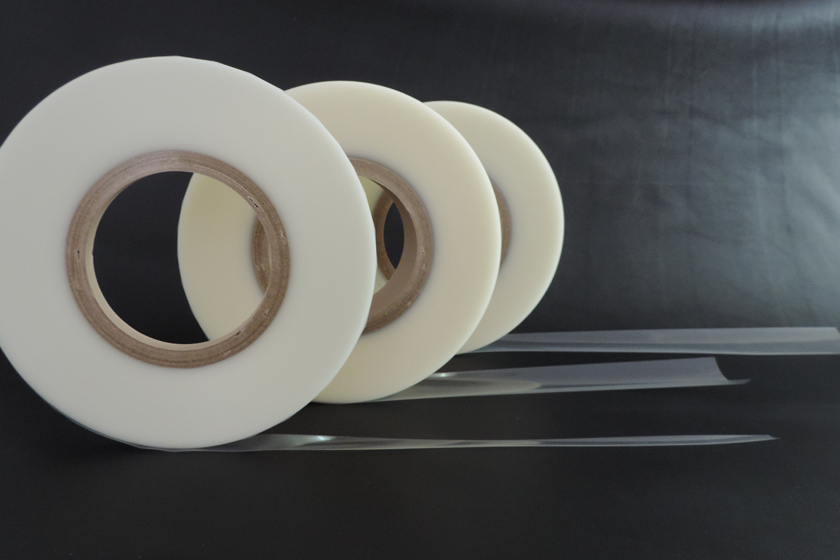

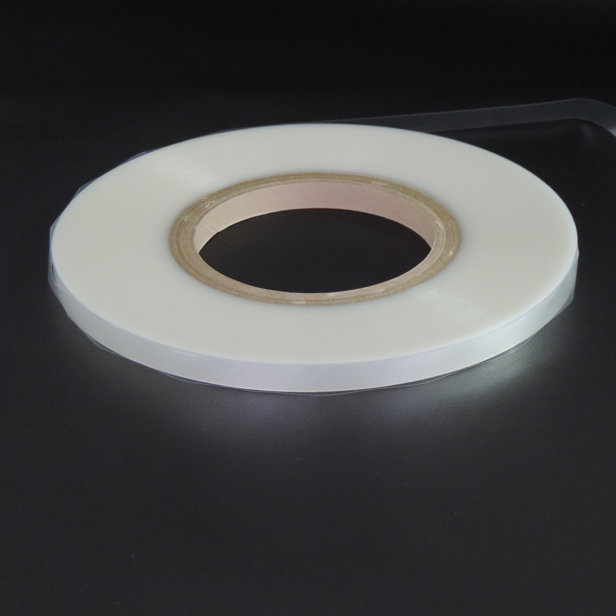

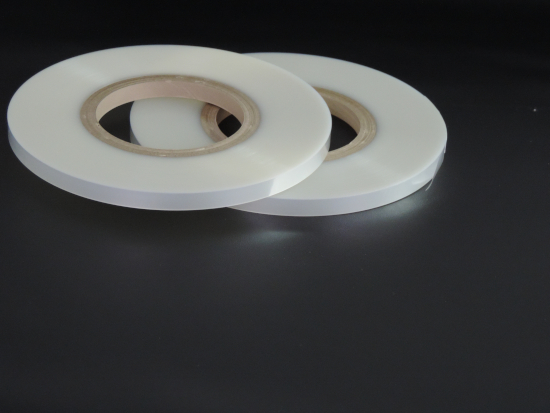

RELEASE FILM

Sell Release film in 1 meter increments.

Normally, it is delivered in rolls, but sheet-like processing is also possible.

After payment is confirmed, it will be delivered to you

within 3 business days (excluding overseas) in principle.

For purchase requests, quotations, grades, etc., please contact the following window.

Heat-resistant RELEASE FILM

Types and characteristics

- Can be used in high temperature range around 200 degrees.

- Fits to any surface conditions.

- Silicone / Fluorine-free product.

- Transmits light in the ultraviolet range.

- Excellent balance between heat resistance and releasability.

- Due to its molecular structure, it is gas permeable.

Main applications

- PC-based coverlay press process

- Release film for pressing (CFRP, GFRP, AFRP, etc.)

- Cure prepreg of glass cloth, carbon fiber, aramid fiber, etc. and epoxy resin

- Release film for molding thermosetting resin

Characteristic table

| Name | Thickness | Processing | Softening Temperature | Tensile Strength MD |

Thermal dimension Change rate MD |

|---|---|---|---|---|---|

| micron | degrees | Mpa | % | ||

| Opulent(TPX) | 50 | gross | 47, 52 | 30, 33 | 1.4, 1.6 |

| 50 | mat | 52 | 32 | -0.6 | |

| 120 | mat | 46 | 26 | -1.6 | |

| 150 | gross | 29, 42 | 19, 22 | 0.7, 1.0 | |

| 150 | mat | 42 | 23 | 0 | |

| 50, 100 | New product : single sided adhesive | ||||

| Name | Thickness | Width | Chief | Peeling force | Residual adhesion rate |

| micro | mm | M | g/50mm | % | |

| Silicon PET | 12~ | 1,120 | 12,000 | 10~50 | 90 and above |

| Negotiable | Negotiable | ||||

High Heat-resistant FILM

Types and characteristics

- Cost reduction is possible as an alternative to fluorine.

- High heat resistance (melting point : 247 degrees, Tg : over 200 degrees).

- Low dielectric (EpsilonGamma = 2.3, tanDelta = 0.0004 (10GHz)).

- Due to low water absorption, electrical characteristics do not change even in high humidity environments.

- Excellent hydrolysis resistance.

- Thickness : 12, 25, 35micro.

Main applications

- High frequency substrate

- Flat cable insulation

Contact us for more details

Inquiry form

Inquiry form