Processing Service

Advanced processing solutions provided

by material professionals

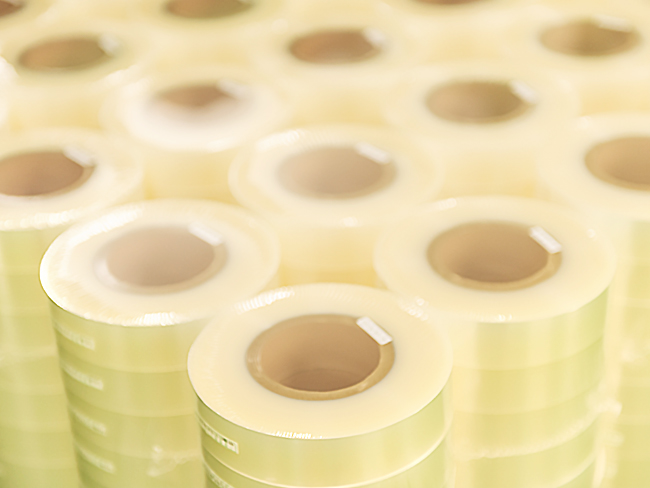

We are a specialized trading company that handles chemical products, but we are also "processing professionals" that support our customers' manufacturing. For many years, we have responded to our customers' detailed requests through slitting, cutting, and punching at the Mito Processing Center.

In addition to that experience and know-how, we have begun collaborating with leading domestic and international partners. We have achieved high-precision processing that was previously difficult to achieve. From prototypes to mass production, we propose optimal solutions that utilize our domestic and international networks.

Processing Service

We propose slit processing and prototype processing that meet the needs of our customers.

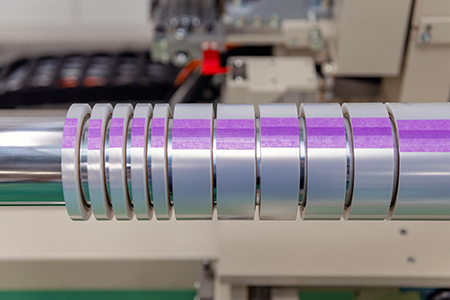

A wide variety of slit processing is required depending on the type, width, length, etc. of the application.

At Fujichemi Trading, we will propose the optimum slit processing method that meets the needs of our customers from our own factory.

Why don't you give shape to the thoughts of "Isn't it possible to do this?" And "I wish this happened!"

We also support narrow and long lengths.

The outer diameter of the product can be wound up to 600 to 700 mm, and the minimum cutting width can be from 5 mm.

In addition, slitting of adhesive tape is also possible in the cut-off process (push-cut process).

The product winding outer diameter can be up to 300mm, and the minimum cutting width is 3mm.

For details, see " Machine capability specifications " and " Cut-off processing (push-cut processing)".

Slit-processed products

Available range

| For small lots | Prototype processing | Mainly slit processing. Test processing can be done from a SINGLE WEB! |

|---|---|---|

| Small roll processing | Available from 1m (Paper tube / Plastic tube). Fluorine, LCP liquid crystal polymer, etc. | |

| Cutting | A4, Round, Rectangular, etc. If you create a mold, you can freely design apron type within 400x550mm. * In addition to general processing, we have a track record of supplying PET and non-woven cut products to Florists. |

|

| Cut off / push off | Adhesive tape etc. can be processed in the specified size | |

| Rewind | Can be played back by a rewinder | |

| Supply | It is possible to process paper tubes to the specified width and supply paper such as PET and PE. | |

| Packing | Shrink packing, Box packing, Simple PE packing, Export packing | |

| Shipping | Small lot to pallet, shipping by mail | |

| Coating | Ideal for companies that want to try materials. | |

| Export/Import service agency | After consultation | |

| Stock keeping | Keep your inventory. | |

| Processing results | Non-woven fabric, Paper, Cover tape, AL / PET, Fluorine film, Various films | |

Machine capability specifications

| Machine | Machine No.1 | Machine No.2 | Machine No.3 | Machine No.5 | Machine No.8 |

|---|---|---|---|---|---|

| Roller surface length | 1,100mm | 1,300mm | 1,600mm | 650mm | 1,500mm |

| Maximum web outer diameter | 700mm | 800mm | 800mm | 800mm | 800mm |

| Winding core | 3inc ~ 6inc | 2inc ~ 6inc | 3inc ~ 6inc | 3inc | 3inc |

| Width that can be set | 50mm ~ 1,000mm | 50mm ~ 1,250mm | 600mm ~ 1,550mm | Up to 540mm | 1,450mm |

| Winding size (products) | 330mm | 600mm | 400mm | 400mm | 700mm |

| Cutting material thickness | 12μ ~ 200μ | 12μ ~ 700μ | 30μ ~ 150μ | - | - |

| Cutting method | Shear cut Razor cut |

Shear cut Razor cut |

Shear cut | Shear cut | Razor cut |

| Winding method | Solid shaft Moving blade:10mm~ Fixed blade:5mm~ |

Solid shaft:10mm~ PX shaft:55mm~ |

PX shaft:100mm~ | Fixed blade: 5.5mm, 5.7mm 9.5mm, 10.0mm 13.5mm, 21.0mm 21.5mm |

Moving blade:5mm~ |

| Product winding Inner core | 1inc, 1.5inc 2inc, 3inc |

2inc, 3inc 80mm, 86mm 4inc, 110mm 5inc, 6inc |

3inc | 2inc 3inc |

3inc |

| Maximum product winding width | 1,000mm | 1,250mm | 1,550mm | 540mm | 1,450mm |

| Adhesive roller | * | * | |||

| film slit | * | * | * | * | * |

| Metal slit (AL / PET, etc.) | * | * | |||

| Non-woven slit | * | * | |||

| Clean room class 10,000 | * | * | * |

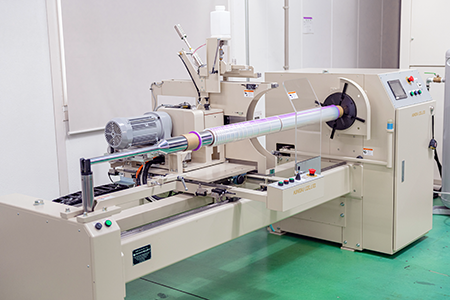

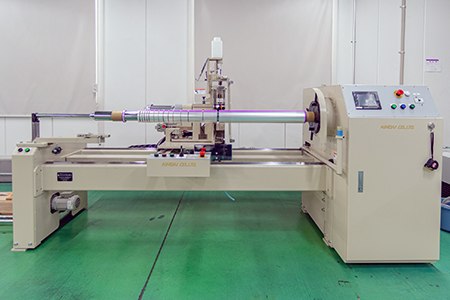

Cut-off processing

(push-cut processing)

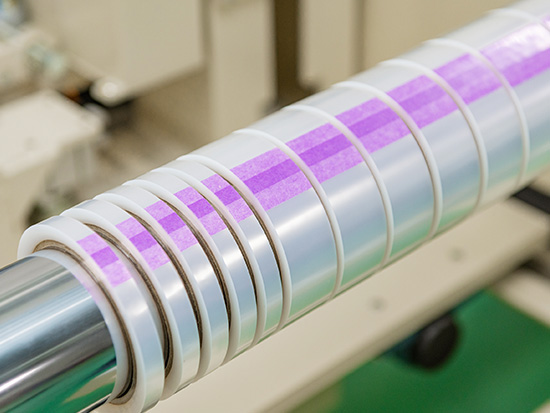

Cut-off processing of adhesive tape (push-cut processing)

Appearance of equipment 1

Appearance of equipment 2

Processing example

Highly heat-resistant double-sided adhesive tape

(0.4mm thick with separator)

Minimum slit width: 3mm~

Fluorine film (from 12μm~)

Machine Introduction

| Maximum roll set width | 1,600mm |

|---|---|

| Raw fabric maximum outer diameter | 150mm ~ 300mm |

| Core size | 1inc, 35mm, 38mm, 2inc, 3inc, 77mm Plastic core (PE core) can be cut |

| Cut width | 1,300mm |

| Cutting width | 3mm ~ |

| Feed accuracy | +-0.1mm |

Thermal lamination

processing services

With our own thermal lamination equipment and business partnerships with companies that have advanced technology, we provide laminated products made from resin films, metal foils, nonwoven fabrics, etc. We also handle prototypes and small-lot sales to meet all of our customers' needs.

Features of thermal lamination processing services

Thermal lamination is an environmentally friendly method of laminating films, sheets, and other substrates directly together using heat and pressure without using adhesives containing organic solvents. Substrates to be laminated include resin films, metal foils, paper, and nonwoven fabrics, and it is possible to laminate two to five layers at a time. Laminated products are used in a wide range of fields, from food packaging to electrical wires, building materials, and electronic materials.

Processing equipment and specifications

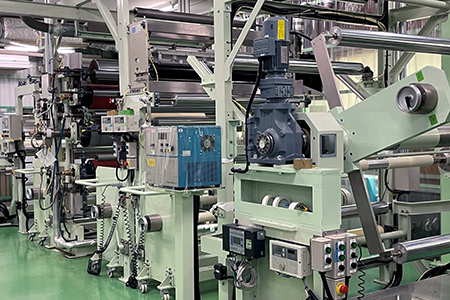

Thermal lamination machine (in a clean room)

Slitting machine

- Thermal Laminating Machine

We have 3 units, one of which is in a clean room (class 10,000) and can be corona treated - Slitting machine

We have 3 machines, and can handle slitting (razor and shear cutting) of laminated products and dividing them into smaller portions.

| processing layer | 1 ~ 5 layers |

|---|---|

| Product width | 100 ~ 1,250mm |

| Product Thickness | 0.06 (6μm) ~ 2mm (foam up to 16mm) |

| Winding length | 20 ~ 4,000m |

| product weight | ~ 700kg |

| Roll Temperature | Rubber roll: up to 120 degrees metal roll: up to 190 degrees |

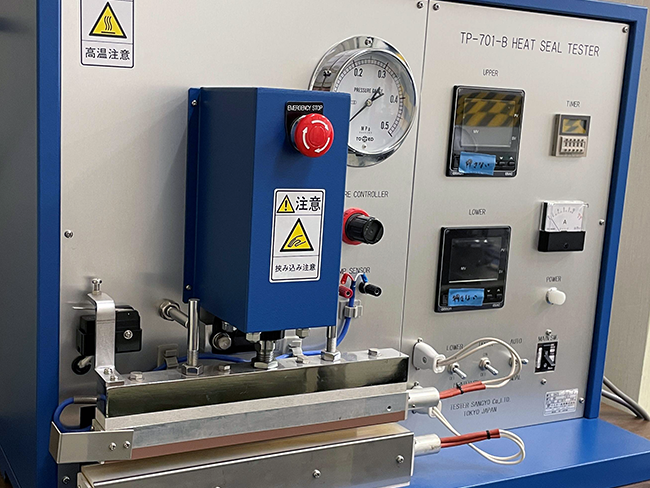

Testing Equipment

Heat Seal Tester

Tensile testing machine (mechanical strength testing machine)

Oken air permeability tester

Processing example

| processing layer | Processing details (example) |

|---|---|

| Single layer | Nonwoven fabric calendaring Cross-linked PE film, foam sheet, etc. stretching processing |

| 2-layer product | PE film / foamed PE sheet Kraft paper / foamed PE sheet |

| 3-layer product | Nonwoven fabric / Porous film / Nonwoven fabric Thermal paper / PE fabric / PE foam sheet |

| 4-layer product | PET film / AL foil / PP film / PET film OPP film / PE film / PE fabric / foam sheet |

| 5-layer product | AL foil / PE film / PE fabric / PE film / PET film Rubber sheet / PE film / SUS foil / PE film / Flame-retardant PE film |

2-layer product : Kraft paper / PE foam sheet

3-layer product : PET film / PE film / non-woven fabric

Plotter processing service

Also suitable for thick materials

Plotter processing without the need for molds

No mold is required, making it ideal for prototyping or small-lot production starting from one item. Using special blades, we can quickly cut materials such as film and urethane into any shape according to the data you provide.

Although it depends on the material, we can also process thick materials up to 100mm thick. We support our customers' development by reducing the cost and delivery time of mold production.

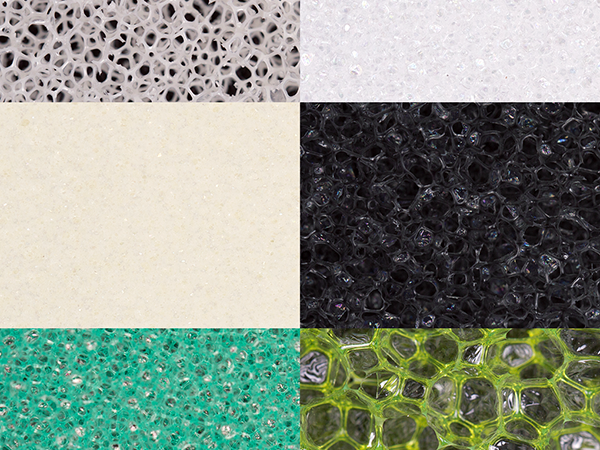

Polyurethane sponge slicing and secondary processing

We provide integrated support from slicing to secondary processing

We slice polyurethane sponge to the thickness you desire. We can also slice thin layers as thin as 1mm, allowing for precise thickness adjustment.

As secondary processing after slicing, we also offer cutting to your specified shape and laminating adhesive tape. We are a one-stop shop that can meet the diverse needs of our customers, from slicing the material to processing the final product.

Various lamination services

From prototypes to mass production

Custom lamination

We laminate a wide variety of materials using heat, pressure, adhesives, or a combination of these. We can bond different materials together, including PU, PE, and PP foam, as well as rubber and felt.

We propose the optimal method according to your needs, from processing with automated machines suitable for mass production to manual work for prototypes and complex specifications. We impart new functionality to materials, improve their strength and durability, and increase the value of our customers' products.

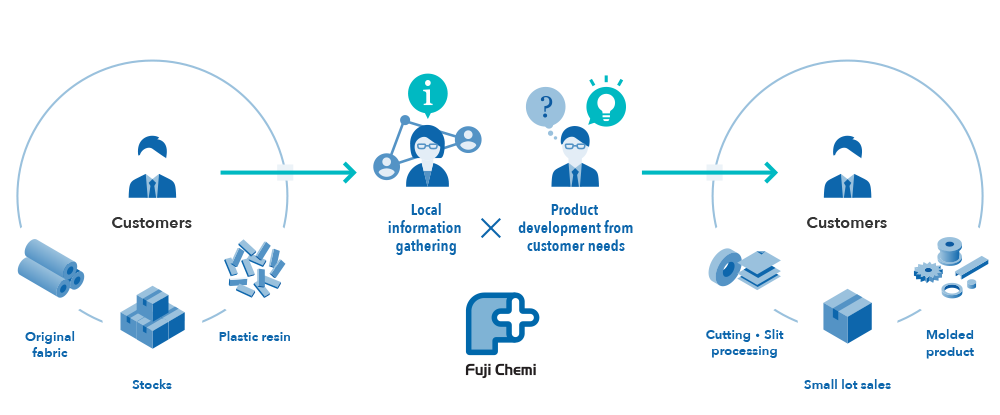

Overseas contract

processing service

We handle everything from processing to import and export.

Contributes to the simplification of commercial distribution.

We operate our own factories not only as a trading company but also in the suburbs of Bangkok, Thailand and Hanoi, Vietnam.

Currently, we manufacture films, tape slits, punching, transport trays, and electric wires. We are entrusted with precision hand processing such as static elimination brushes.

Please feel free to contact us if you are a company that is confident in its technology but has trouble expanding overseas, such as lack of factory management know-how overseas or no human resources who can work overseas.

Factory in Thailand

Factory in Thailand

Factory in Vietnam

Manufacture by commissioning in Thailand and Vietnam

We have our own slit equipment in Mito, Bangkok and Hanoi, and sell films / paper / non-woven fabrics in the size desired by local customers. In addition, we have inventories for each width locally as needed, and we also support quick delivery and import / export, which contributes to the simplification of the commercial distribution of our business partners.

Main processing contents

- Slitting: Shear cut, razor cut, and push cut processing

Nonwoven fabrics, resin films, etc. can be slit to any desired width.

By using shear cuts and razor cuts, it can also be used on thick or soft materials.

We can also cut adhesive tapes using the cut-off process. - Thomson die punching

Using a Thomson die, sheets, films, foam products, etc. are cut into specified shapes.

Although it is necessary to create a mold first, this method is suitable for mass production of the same size. - CNC cutting

This is a process in which sheets or film products are cut directly using a razor blade or similar equipment under computer control based on a blueprint.

It is suitable for processing a wide variety of products in small lots, and is primarily used for prototyping and semi-mass production. - Press processing

This process involves pressing a punch (male mold) against resin or metal to perform punching, bending, etc. - Vacuum forming

This process involves applying heat to a thermoplastic plastic sheet to soften it, then pressing the sheet against a mold in a vacuum to form the desired shape.

We are able to produce small lots of complex shaped products and prototypes at low cost and in a short period of time. - Injection Molding

This process involves heating thermoplastic resin to a softening temperature, then pouring it into a mold to fill it and form it.

Although it is necessary to create a mold first, this method is suitable for mass production.

Various processing

prototype services

We propose processing technology and manufacturing methods at the development / prototyping stage.

We provide proposals for optimal punching and laminating processing and sample cutting according to the material characteristics, shape, and adhesive material used for multilayer films. It saves you a lot of trouble at the manufacturing site, such as supporting mass production after trial production. Please feel free to contact us, no matter how small your worries.

List of services

- Small-lot film prototype

We can handle small-lot film prototypes. We can make films using a variety of thermoplastic resins. - Product mockup, Various jigs, Rubber product

We provide product mockups for product development and presentations, various jigs that are precisely manufactured and processed based on customer 3D data and samples, and prototyping services using urethane, silicone rubber, etc., using 3D data. - Vacuum forming Design, prototype

This is a prototyping service for "vacuum forming," a process in which thermoplastic plastic is heated and then vacuum-fitted to a mold to produce a product.

Inquiry form

If you have any comments, questions, or inquiries regarding our products and services, please use the form below.

Inquiry form

Inquiry form